CAD Conversion

Conceptual Design

Design optimization

Stage drawings

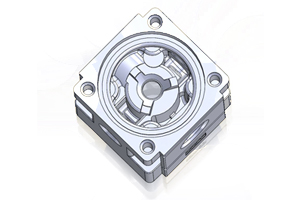

Casting drawings

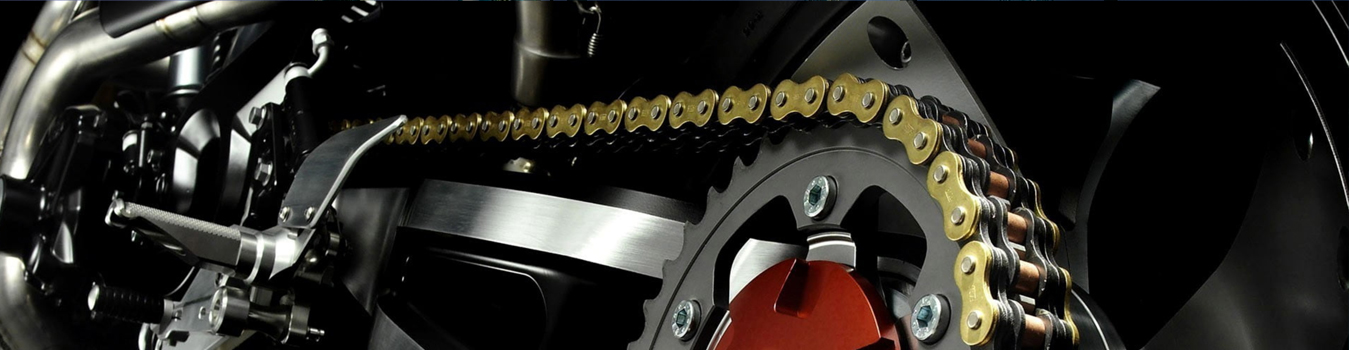

Reverse engineering

Parametric design

Rendering and animation

Quantity Takeoff & Estimating Services

Structural Steel Drafting & Detailing

Architectural Miscellaneous

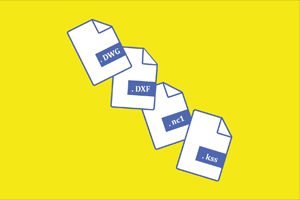

File Type For Shipment

Steel Connection Design

PE Sign & Stamping

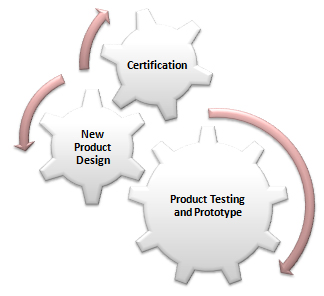

Computer aided Engineering is a software based methodology where we are intended to use the Concepts of Finite element Methods and Computational Fluid Dynamics to Model the real time problems to the reliable Numerical Modelling.

With The application of CAE, Number of iterations for the Prototyping is Drastically reduced by virtually simulating the possible number of combinations In software and Prototyping the Model with the most desired Results.

| STATIC | DYNAMIC | THERMAL | EXPLICIT | FATIQUE LIFE | OPTIMIZATION |

|---|---|---|---|---|---|

| Structural strength | Transient Loads | Steady state | Drop test | LCF/HCF | Weight |

| Linear /Non linear | Modal | Transient | Crash test | Total Life time | Topology |

| Buckling | Harmonic | Welding simulations | Metal Forming | Fatigue FOS |

Optimuz has a team of dynamic young design engineers who have expertise in multiple CAD/CAE software; with this strong team we invite contracts/partnerships on outsourcing the engineering design activity at a competitive cost.